Meltio Materials

Metal 3D Printing Wire

Meltio’s Laser Metal Deposition process achieves exceptional material mechanical properties using single, dual and quad wire. Choose the ideal welding wire for your application: unlimited third-party commodity material or qualified Meltio Wire Materials that secure the user experience.

Single, Dual & Quad Wire

Metal 3D Printing

Achieve exceptional mechanics decreased thermal stress and near isotropic properties. Available in welding wire between 0.8 and 1.2 mm in diameter.

Single Wire

The bulk of the 3D printing process is built around wire, the safest, cleanest and easiest to work with metal feedstock.

>99.998 % Densification

Meltio’s LMD process produces fully dense parts with superior microstructure; reaching up to 99.998 % densification.

Dual & Quad Wire

Combine different metal materials in a single part. The wire-switching process is automatic, quick and clean.

Layer Height

From 0.6 to 1.2 mm layer heights.

Under some conditions, Meltio’s surface roughness using wire outperforms those produced with powder based processes.

Unlimited Third-party Material Choice

Download our Printable Materials list

Download our Printable Materials list

Download our Printable Materials list

First-Time-Right with Meltio Materials

Guaranteed part properties with optimized print profiles.

- Meltio Mild Steel ER70-S

- Meltio Stainless Steel 316L

- Meltio Stainless Steel 308L

- Meltio Stainless Steel 17-4PH

- Meltio Tool Steel H11

Meltio Mild Steel

Meltio Stainless Steel

17-4PH

A martensitic precipitation hardened stainless steel capable of achieving high hardness while offering excellent corrosion resistance. It is widely employed in the oil & gas, and aerospace.

316L

Highly corrosion-resistant grade of austenitic stainless steel with great mechanical properties. Ideal for marine and chemical applications.

308L

All-around stainless steel with adequate corrosion resistance and good mechanical properties.

Meltio Tool Steel

Meltio Invar

Meltio Titanium

Dual Wire

Metal 3D Printing

Dives deep into the details of how our second-generation deposition head has two built-in wire feeders, allowing the Meltio products to smoothly switch between two materials within a single part.

Metal 3D Printing Solutions

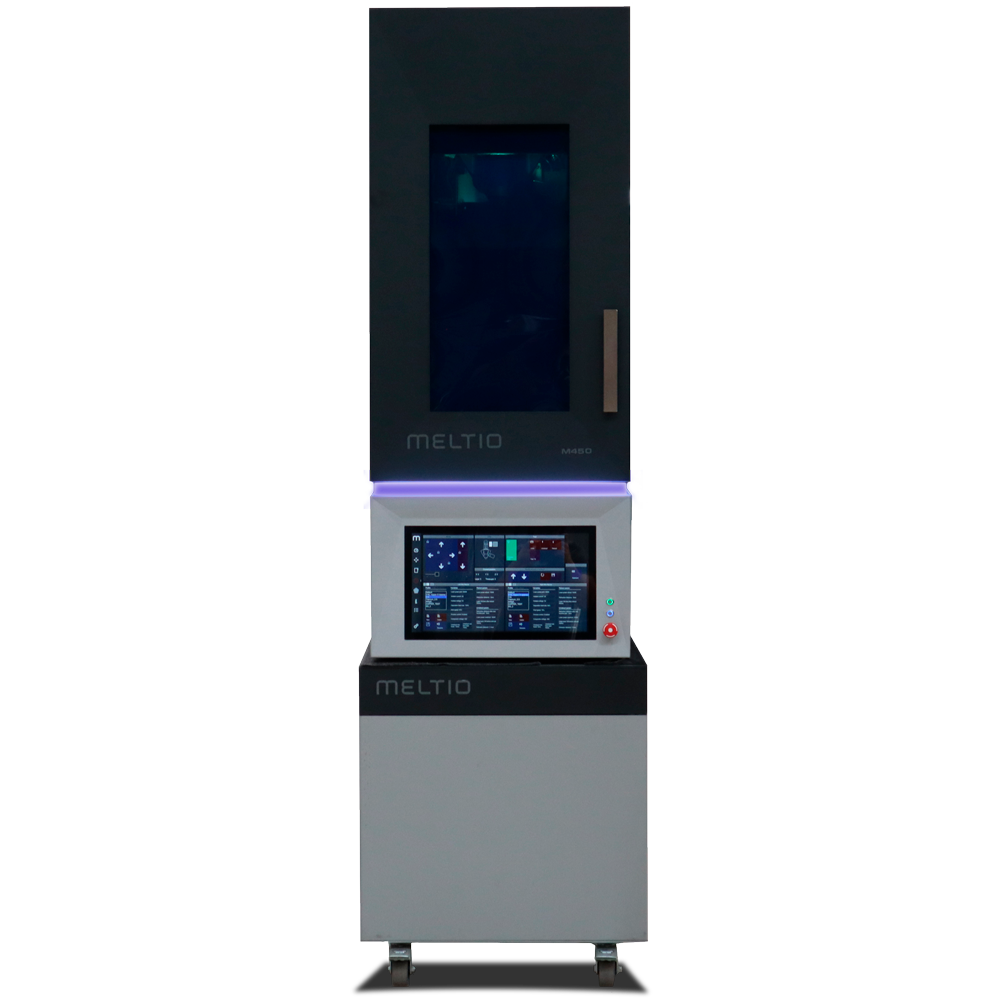

Meltio M450

3D Printer

Turn-key Metal 3D Printer.

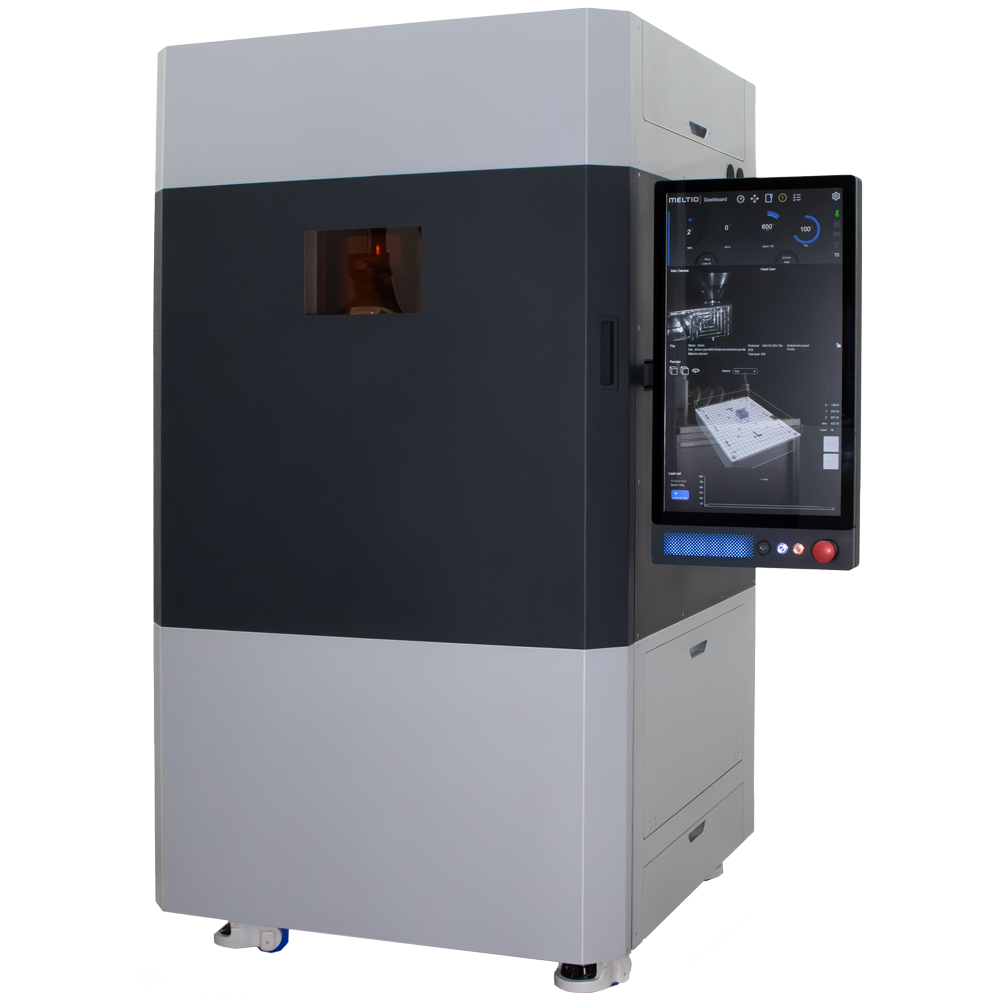

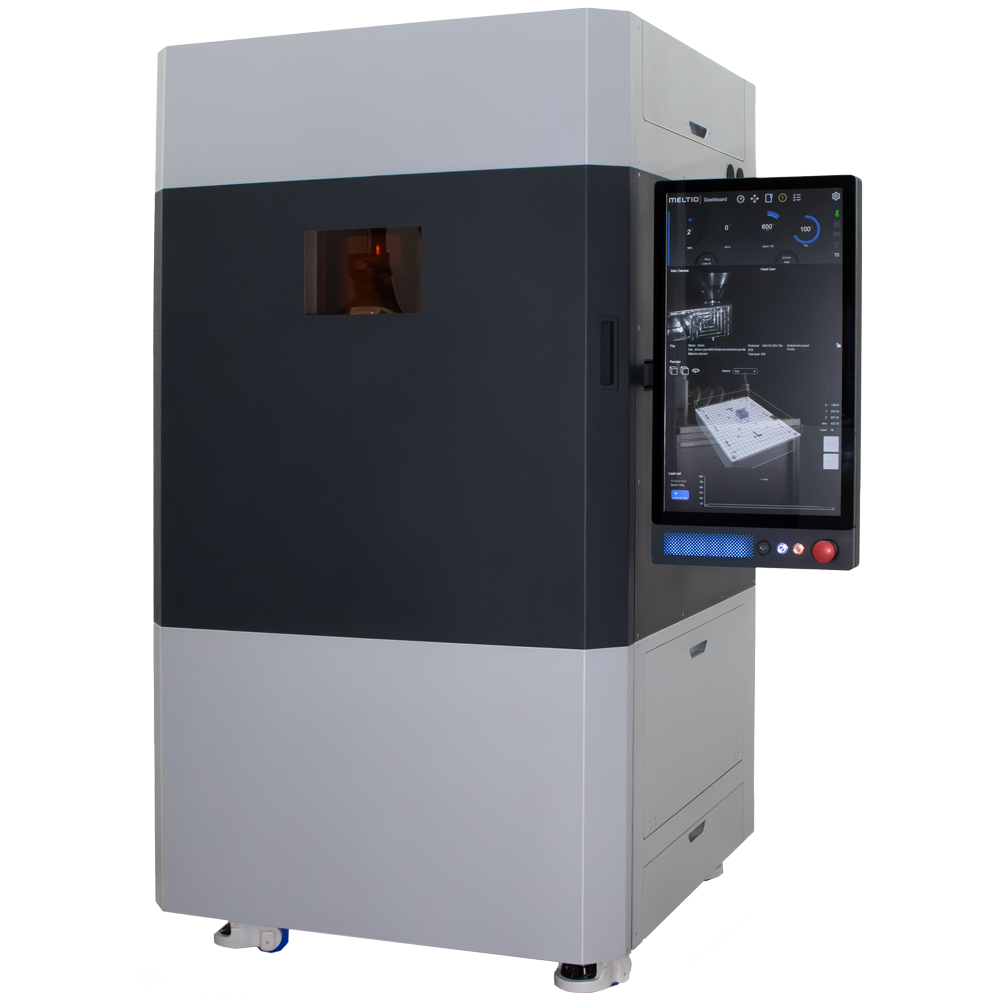

Meltio M600

Industrial 3D Printer

Ideal companion for your industrial operations.

Meltio Engine

CNC Integration

Hybrid Manufacturing System.

Meltio

Robot Cell

Turn-key plug-and-play Solution.

Meltio Engine

Robot Integration

For large, complex parts, laser cladding, and repairing.

Meltio M450

3D Printer

Turn-key metal 3D printer for near-net shape manufacturing.

Meltio M600

Industrial 3D Printer

Ideal companion for your industrial operations.

Meltio

Robot Cell

Turn-key plug-and-play Solution.

Meltio Engine

Robot Integration

For large, complex parts, laser cladding, and repairing.

Meltio Engine

CNC Integration

Hybrid Manufacturing System.